UREXCEED

PU Foam Machines for Cold Chain Manufacturing

Tailored foaming power to match your production scale — from small-batch molds to large-scale cold storage lines.

Polyurethane foaming is the heart of insulation performance in refrigerators, cold storage panels, and insulation boxes.

At UREXCEED, we provide three main PU foaming machine series — High Pressure PU Foam Machines, Cyclopentane PU Foaming Machines, and Low Pressure Foam Injection Machines — each designed to fit a different stage of your business journey.

Whether you’re testing markets as a startup or expanding into global cold chain manufacturing, our foaming solutions ensure consistent density, minimal waste, and seamless integration with your workflow.

Three Types of UREXCEED PU Foam Machines in Cold Chain Industry

There are three types of polyurethane foaming machines designed for producing cold chain products, high pressure PU machines, cyclopentane high pressure PU molding machine and low pressure PU foam machines. No matter how big your industry is, you can find a suitable PU foaming machine here.

For Large-Scale Production

High Pressure PU Machine

UREXCEED High Pressure Polyurethane Foaming Machine is a heavyweight for large-scale cold chain production, designed to deliver high efficiency, precision, and stability for mass-manufacturing scenarios. Equipped with advanced servo-driven systems and intelligent control technology, it solves the pain points of uneven foam density and low production capacity in large-volume workshops, making it the first choice for enterprises with mature production lines and high-output demands.

High Efficiency

15-30 kg/min foam output, supporting 200+ production cycles per day—ideal for full-auto refrigerator lines and cold storage panel factories.

Precision Mixing

Servo-driven metering pumps with ±1% mixing accuracy, ensuring uniform foam density (30-60 kg/m³) for stable insulation performance.

The Specification of High Pressure PU Foaming Mahcine

No. | Item | Technical Parameter |

1 | Foam application | PU Rigid Foam |

2 | Raw material viscosity(22ºC) | POL~2500mPas |

3 | Injection pressure | 10~20Mpa (adjustable) |

4 | Injection Output (mixing ratio 1:1) | 750-3750g/s |

5 | Mixing ratio range | 1:3~3:1(adjustable) |

6 | Hydraulic system | Output 10L/min |

7 | Tank volume | 250L |

8 | Input power | Three-phase five-wire,380V 50HZ |

Use Cases of High Pressure Polyurethane Machines

High Pressure Polyurethane Machine for Wine Refrigerator

More Details

High Pressure Polyurethane Machine for Wine Refrigerator

More Details

High Pressure Polyurethane Machine for Wine Refrigerator

More Details

High Pressure Polyurethane Machine for Wine Refrigerator

More Details

Eco-Friendly Refrigeration

Cyclopentane High Pressure Polyurethane Molding Machine

As a green and compliant solution for refrigeration manufacturing, UREXCEED Cyclopentane Polyurethane Foaming Machine uses cyclopentane (an environmentally friendly blowing agent) to replace traditional HCFCs, fully meeting global strict environmental standards such as EU ROHS/REACH. It integrates explosion-proof safety design, energy-saving technology, and precise foaming control, especially suitable for enterprises that focus on high-end, eco-friendly refrigeration products and need to enter international markets (such as Europe, North America).

Environmental Compliance

Uses cyclopentane (zero ODP, low GWP) as blowing agent, fully compliant with EU ROHS/REACH and global environmental standards—perfect for high-end refrigerators.

Explosion-Proof Design

Explosion-proof design (EX d IIB T4 Gb) with gas leakage detection system, ensuring safe operation in closed production environments.

The Specification of Cyclopentane High Pressure Polyurethane Molding Machine

serial number | project | Technical Parameters |

1 | Applicable foam types | Naphthene |

2 | Applicable raw material viscosity (20℃) | Polyether polyol POL: ~2500MPas Polyisocyanate ISO: ~1000MPas |

3 | Injection pressure | 10~20Mpa(adjustable) |

4 | Injection flow rate (mixing ratio 1:1) | Maximum 2500 grams per second |

5 | Mixing ratio range | 1:3~3:1 (adjustable) |

6 | Tank volume | 300L |

7 | Metering pump motor | Power: 22Kw Speed: 1450r/m |

8 | Total power | 50KW _ |

9 | Using electric | 380V 50HZ |

High Pressure Polyurethane Machine for Wine Refrigerator

More Details

High Pressure Polyurethane Machine for Wine Refrigerator

More Details

High Pressure Polyurethane Machine for Wine Refrigerator

More Details

Small-Batch & Custom Production

Low Pressure Polyurethane Machinery

UREXCEED Low Pressure Polyurethane Foaming Machine is a cost-effective and flexible choice for small-batch production and startups. With a compact structure, easy operation, and low initial investment, it lowers the threshold for entering the cold chain manufacturing industry. It adopts mechanical stirring mixing technology, which can flexibly adjust foam density and adapt to various small-scale production needs—whether it’s testing new products, customizing small insulation parts, or building small workshops, it can meet the basic foaming requirements stably.

Flexible & Easy

5-12 kg/min foam output, compact design (1.5×0.8×1.2m) suitable for small workshops—no professional operator required

Low Investment

Lower upfront investment vs. high-pressure models, ideal for startups testing markets or producing custom insulation parts (e.g., small insulation boxes, fridge door liners).

No. | Item | Technical Parameter |

1 | Foam application | Rigid foam |

2 | Raw material viscosity(22ºC) | POL ~3000CPS |

3 | Injection Output | 1kg/s |

4 | Mixing ratio range | 100:28~48 |

5 | Mixing head | 2800-5000rpm, forced dynamic mixing |

6 | Tank Volume | 120L |

7 | Compressed air requirement | dry, oil free P:0.6-0.8MPa |

8 | Nitrogen requirement | P:0.05MPa |

9 | Temperature control system | heat:2×3.2kW |

10 | Input power | three-phrase five-wire,380V 50HZ |

11 | Rated power | about 11KW |

12 | Color( customizable) | Cream-colored/orange/deep sea blue |

High Pressure Polyurethane Machine for Wine Refrigerator

More Details

High Pressure Polyurethane Machine for Wine Refrigerator

More Details

High Pressure Polyurethane Machine for Wine Refrigerator

More Details

Quick Comparison of UREXCEED PU Foam Machines in Cold Chain Manufacturing

| Dimension | High-Pressure | Cyclopentane | Low-Pressure |

|---|---|---|---|

| Core Positioning | High Efficiency | Eco-Friendly | Flexible Entry |

| Daily Output | 1600–2400 pcs | 1200–1800 pcs | 400–960 pcs |

| Customer Stage | Mature | Growth / Export | Startup / Trial |

| Key Advantage | Precision, Speed | Green, Safe, Energy-saving | Low Cost, Easy Operation |

Not sure which fits?

Tell us your production goals — we’ll run beside you to choose the right match.

Services & Support of UREXCEED for PU Machines

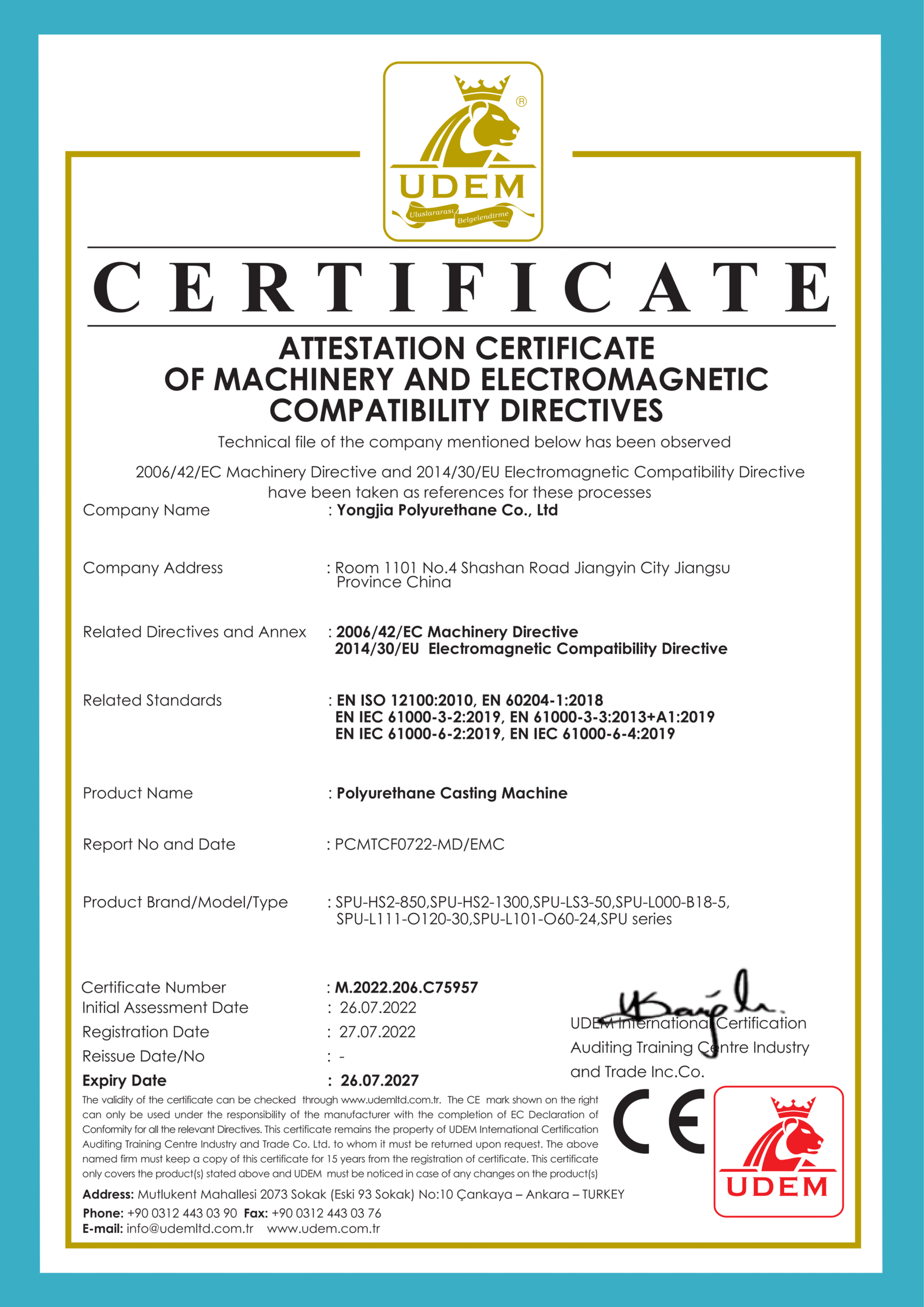

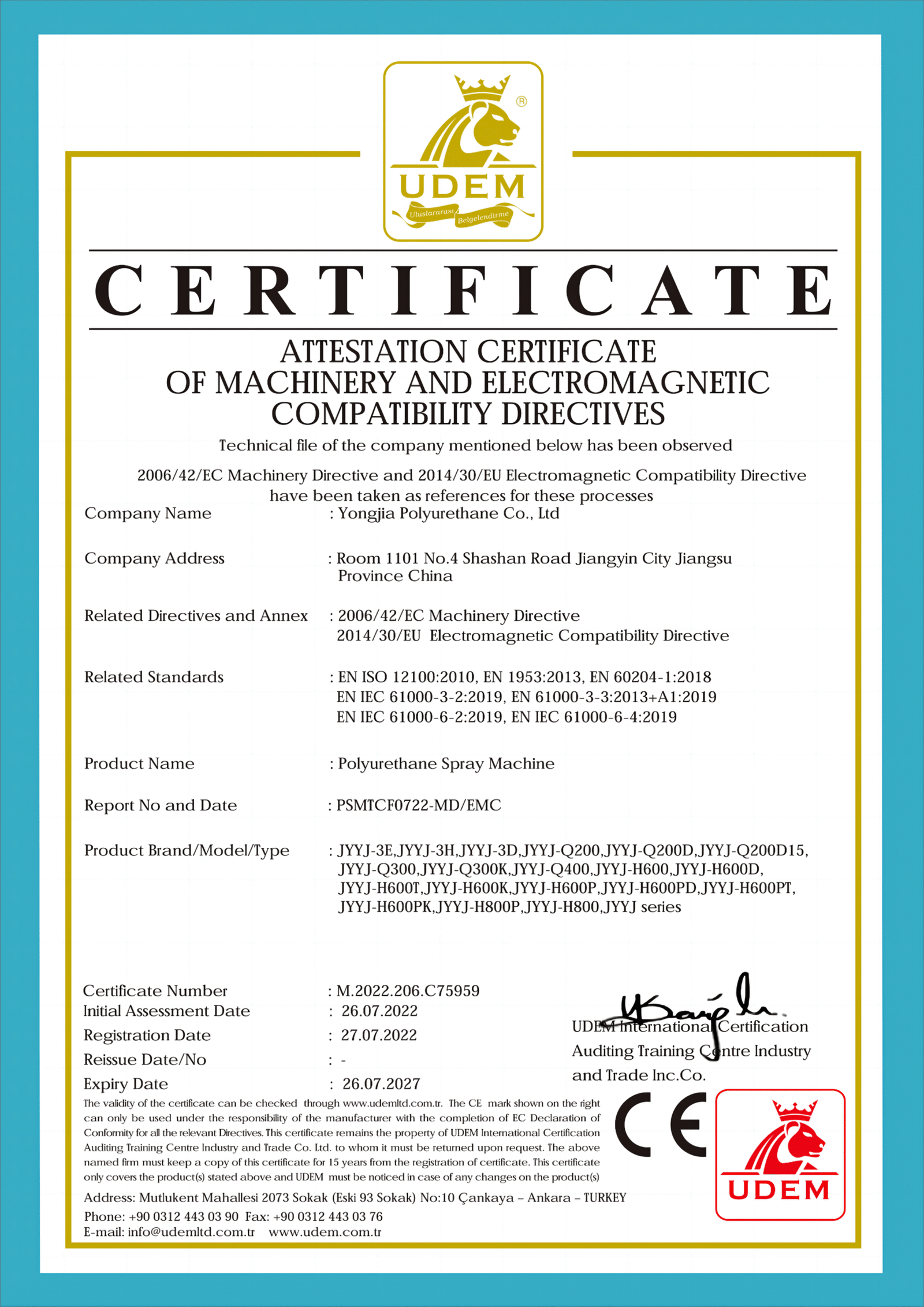

Certifications of

UREXCEED PU Foam Machines

Customers of

UREXCEED PU Foam Machines

UREXCEED has brought high-quality polyurethane foaming machines to customers in more than 100 countries and regions around the world.

Latest News

Of UREXCEED PU Foam Machines

You May Also Need Except PU Machines