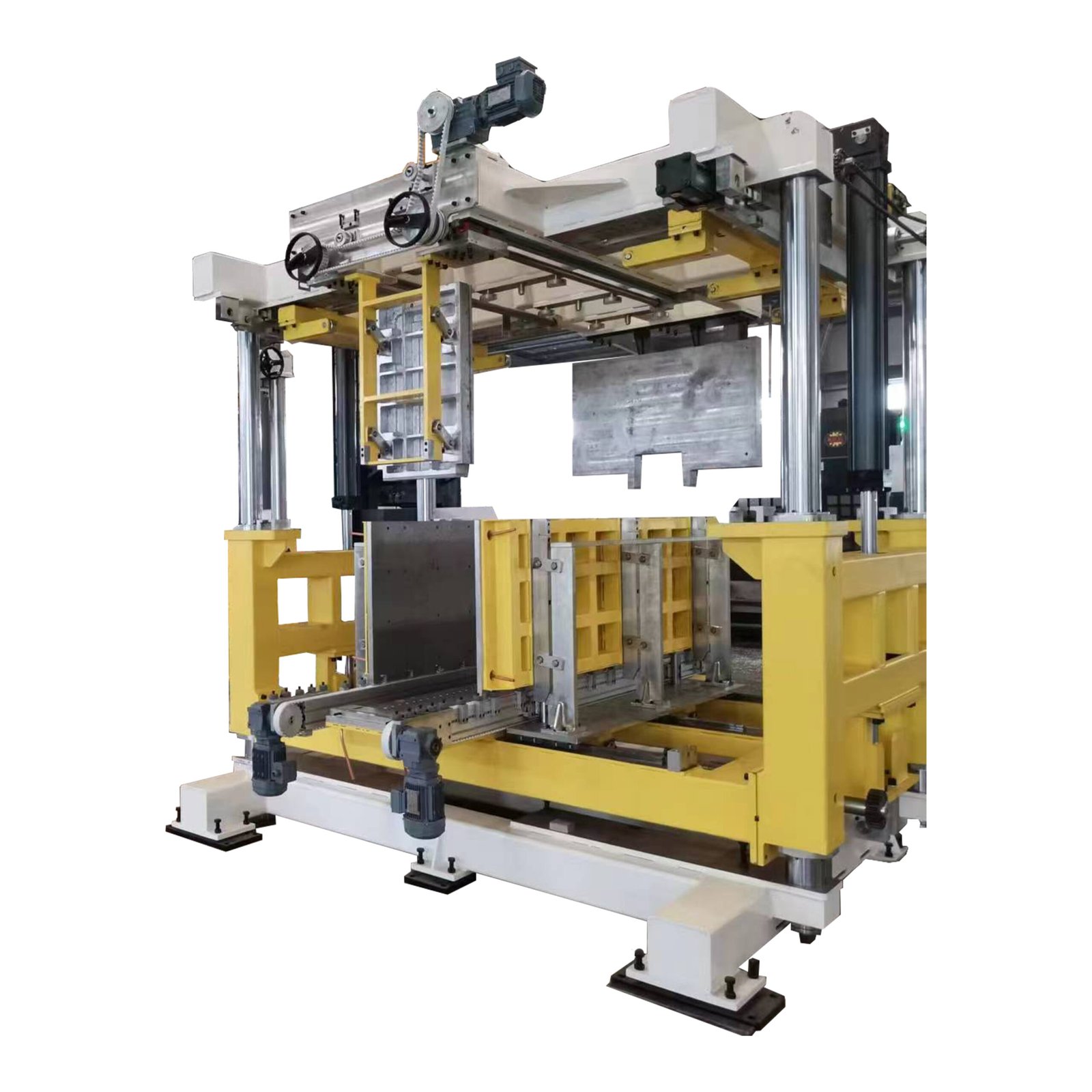

High Pressure Pressure Polyurethane Machine for Display Fridge

Make display fridges both "clear & attractive" (fog-free glass) and "long-lasting fresh" (qualified insulation)

Why Display Fridges Need Specialized High Pressure Polyurethane Machine

As “visual marketing tools” at retail terminals, display fridges need to meet both “large-area glass high-def display” and “2-10℃ precise temperature control” requirements. This demands gap-free insulation filling at glass edges (to prevent fogging) and uniform density in irregular structures (like curved doors and multi-layer platforms) to avoid cold loss.

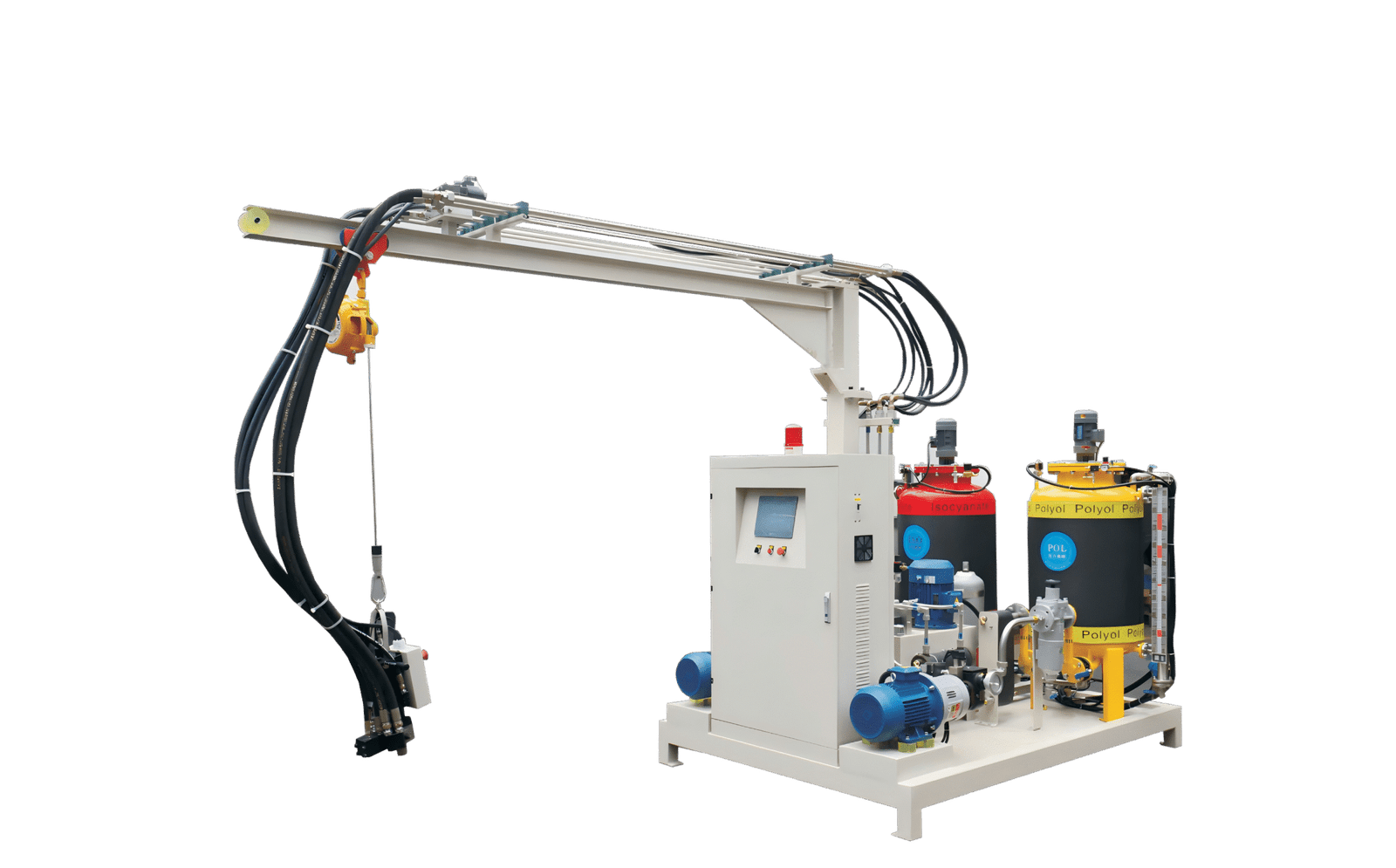

UREXCEED’s high pressure polyurethane machine for display fridges achieves ±1% precision control within 38-50kg/m³ density range through accurate metering system and intelligent pressure control. It especially optimizes foaming in the 3cm area around glass, providing professional solutions for supermarket island fridges, bakery display cases, beverage coolers, etc.

Different Types Display Fridge UREXCEED High Pressure Polyurethane Machine Makes

UREXCEED high pressure polyurethane machines are suitable for the manufacture of a variety of display fridge.

Bakery Display Fridges

Supermarket Island Fridges

Beverage Display Fridges

Custom Irregular Display Fridges

Differentiated Design of High Pressure Polyurethane Machine for Display Fridges

We will explain in detail the advantages of UREXCEED High Pressure Polyurethane Machine for Display Fridges and let customers understand how UREXCEED High Pressure Polyurethane Machine for Display Fridges can help customers produce high-quality display fridge.

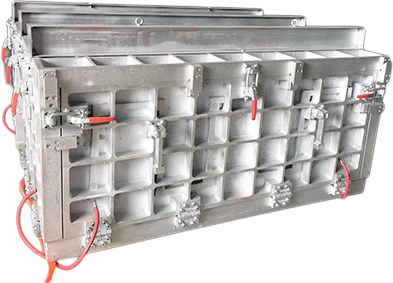

Adopting "stepwise pressure compensation" technology, foam density in the 3cm range around glass is increased to 50kg/m³, forming a "sealed insulation ring"—fogging reduced by 90%, cold leakage rate below 5%;

5-stage injection program supports foaming of complex structures like curved doors and sloped platforms, with no dead corners in foam filling, suitable for 80-220cm high display fridges;

15-30kg/min foam output, capable of producing 50+ standard display fridges per shift, material utilization rate up to 98% to reduce waste costs;

Closed material system + automatic solvent cleaning, VOC emissions meet EU REACH standards, foam free TDI <0.1%, suitable for food-grade display scenarios.

Technical Specifications of High Pressure Polyurethane Machine For Display Fridge

| Parameter | Details | |

|---|---|---|

| Working Pressure | 120-200bar (adjustable) | |

| Metering Accuracy | ±1% | |

| Foam Density | 35-55kg/m³ (optimized 38-50kg/m³ for display fridges) | |

| Formula Storage | 120 sets | |

| Mold Change Time | ≤30 minutes | |

| Power Requirement | 380V/3PH/50Hz (220V optional) | |

| Warranty | 5-year core components |

Ready to Craft Display Fridges That Protect & Impress?

Tell us the size, style, and daily output, and we will customize the equipment solution for you.

More About UREXCEED High Pressure Polyurethane Machine For Display Fridge

- Custom Tuning: We adjust foam density, output rate, and mixing parameters to match your wine fridge’s size, design, and insulation needs.

- Turnkey Setup: On-site installation, commissioning, and 1-day operator training (or 2-hour online sessions for remote teams).

- 24/7 Remote Support: Resolve 90% of issues via video call – minimize downtime for small-batch production.

- Mold Collaboration: Partner with our mold engineers to design foaming-compatible molds for your unique wine fridge styles (e.g., curved doors, dual-zone cavities).

High Pressure Polyurethane Machine For Display Fridge

Customer Case Study

FAQs of High Pressure Polyurethane Machine For Display Fridge

More questions of UREXCEED high pressure PU machines you may want to know for manufacturing display coolers.

Solution: Adopted display fridge-specific high-pressure foaming machine, optimized glass edge foaming with stepwise pressure compensation, and customized multi-layer platform filling program.

A Supermarket Chain Display Fridge Upgrade Project