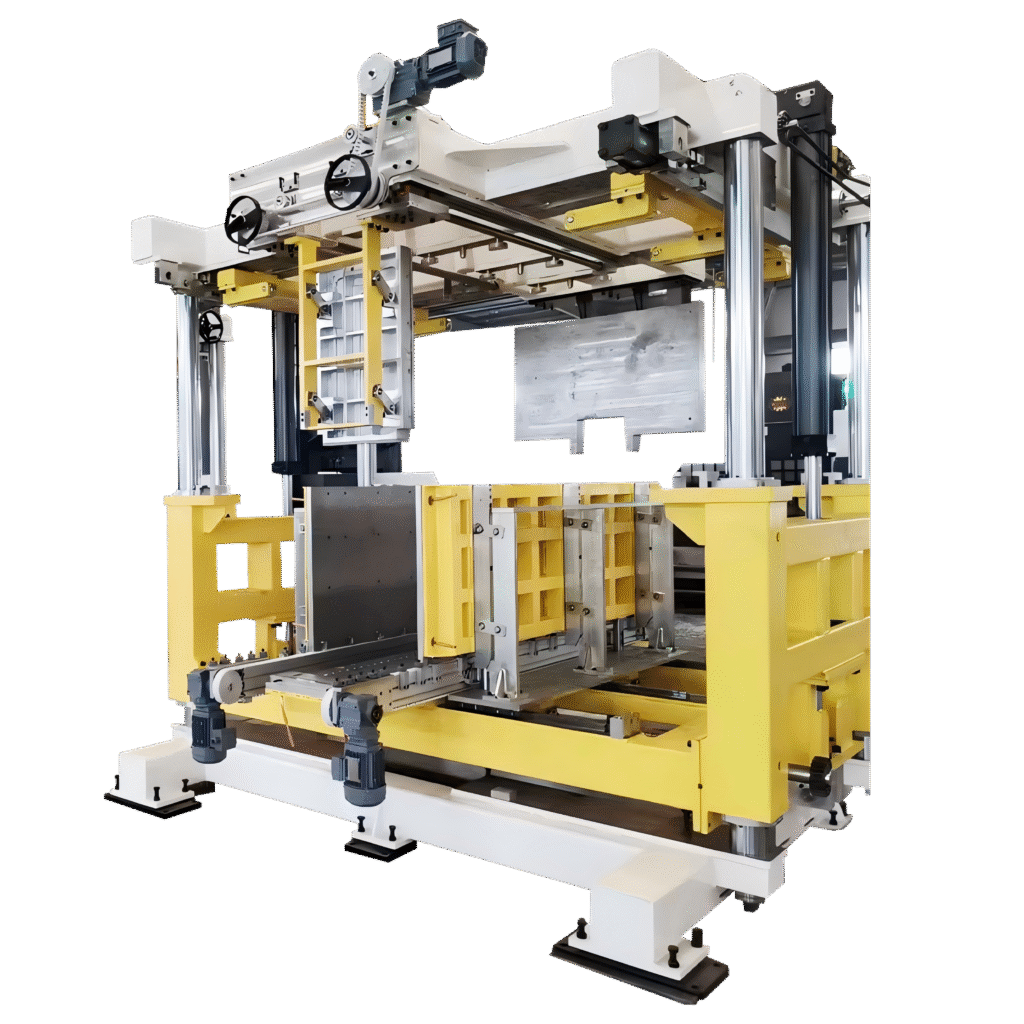

PU Mold Fixture for Refrigerator

Improve mold positioning accuracy, reduce mold change time, ensure stable foaming process, lower product defect rate

Why Refrigerator Mold Need Specialized PU Molds Fixture

PU molds withstand 10-30bar internal pressure during foaming. Inaccurate positioning or uneven clamping force can cause mold displacement and excessive clamping gaps, directly leading to quality issues like foam overflow and uneven density (defect rate up to 8-15%). Meanwhile, traditional clamping methods take 40-60 minutes for mold changes, seriously affecting production efficiency.

UREXCEED PU mold fixtures are specially designed for polyurethane foaming process. Through high-precision guiding and positioning system (±0.1mm) and uniform clamping device, they ensure mold stability during high-pressure foaming. The modular design reduces mold change time to 15-20 minutes, adapting to various PU molds for refrigerators, incubators, auto parts, etc., providing reliable guarantee for mass production.

Adaptation Scenarios of PU Mold Fixture

UREXCEED PU molds fixtures are suitable for the manufacture of a variety of products.

Refrigeration Equipment Molds

Insulation Box/Barrel Molds

Automotive PU Component Molds

Custom Large Molds

How UREXCEED PU Mold Fixture Elevates Fridge Production

We will explain in detail the advantages of UREXCEED PU mold fixture and let customers understand how UREXCEED PU mold jig can help customers produce high-quality fridge.

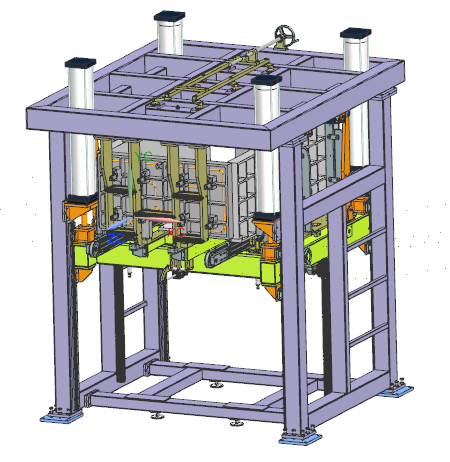

High-precision positioning system

Combining precision guide rails and positioning pins, the positioning accuracy reaches ±0.1mm, ensuring uniform mold clamping gap (≤0.2mm). It fundamentally avoids foam flash and missing material caused by mold displacement, increasing product qualification rate by over 15%.

Modular clamping components + quick locking devices, combined with mold parameter memory function, reduce single mold change time from traditional 40 minutes to 15-20 minutes, increasing small-batch multi-variety production efficiency by 60%.

Quick mold change mechanism

Uniform clamping technology

Multi-point synchronous clamping design (4-12 optional clamping points) ensures uniform mold force (clamping force deviation ≤5%), avoiding local deformation and extending mold service life by over 30%. Clamping force can be steplessly adjusted (5-50kN) according to mold size.

Main body is precision machined with high-strength cast iron (HT300). Key components have hardened surfaces (HRC55-60) with food-grade anti-rust coating, resistant to foaming material corrosion, adapting to humid workshop environment, extending maintenance cycle to 12 months.

Durable and corrosion-resistant structure

Technical Specifications of PU Mold for Bar Fridge

| Parameter | Details |

|---|---|

| Mold Material | S50C alloy steel (partial nitriding) |

| Compatible Fridge Sizes | Width: 40-100cm; Height: 50-120cm; Depth: 40-60cm |

| Foam Density Control | 35-48kg/m³ (up to 48kg/m³ at door edges) |

| Molding Precision | ±0.2mm (overall), ±0.1mm (glass fitting area) |

| Minimum Insulation Thickness | 20mm |

| Changeover Time | <30 minutes (same series, appearance changes) |

| Service Life | 50,000-100,000 cycles (depending on production plan) |

| Food Contact Certification | FDA 21 CFR 177.1350 |

| Warranty | 5-year structural warranty; 1-year warranty on wear parts |

Ready to Craft Fridges Mold Fixture That Protect & Impress?

Tell us the size, style, and daily output, and we will customize the equipment solution for you.

More About UREXCEED PU Mold Fixture for Refrigerator

- Custom Tuning: We adjust foam density, output rate, and mixing parameters to match your wine fridge’s size, design, and insulation needs.

- Turnkey Setup: On-site installation, commissioning, and 1-day operator training (or 2-hour online sessions for remote teams).

- 24/7 Remote Support: Resolve 90% of issues via video call – minimize downtime for small-batch production.

- Mold Collaboration: Partner with our mold engineers to design foaming-compatible molds for your unique wine fridge styles (e.g., curved doors, dual-zone cavities).

PU Mold Fixture for Refrigerator

Customer Case Study

FAQs of PU Mold Fixture for Refrigerator

More questions of UREXCEED low pressure PU machines you may want to know for manufacturing wine coolers.

Solution: Adopted UREXCEED 8-point PU mold fixtures, with precision positioning system controlling deviation within 0.1mm; modular design achieved 20-minute quick mold change.

A Freezer Manufacturer's Mold Fixture Upgrade Project Inaccurate positioning of traditional fixtures caused door foaming thickness deviation (1-2mm) and assembly difficulties; long mold change time (50 minutes/set) made it difficult to handle multi-variety orders.