PU Mold for Upright Freezer

Durable, high-precision molds that create uniform insulation – keeping upright freezers at -18℃ reliably, even in tall 200+cm designs.

Why Upright Freezers Need Specialized PU Molds

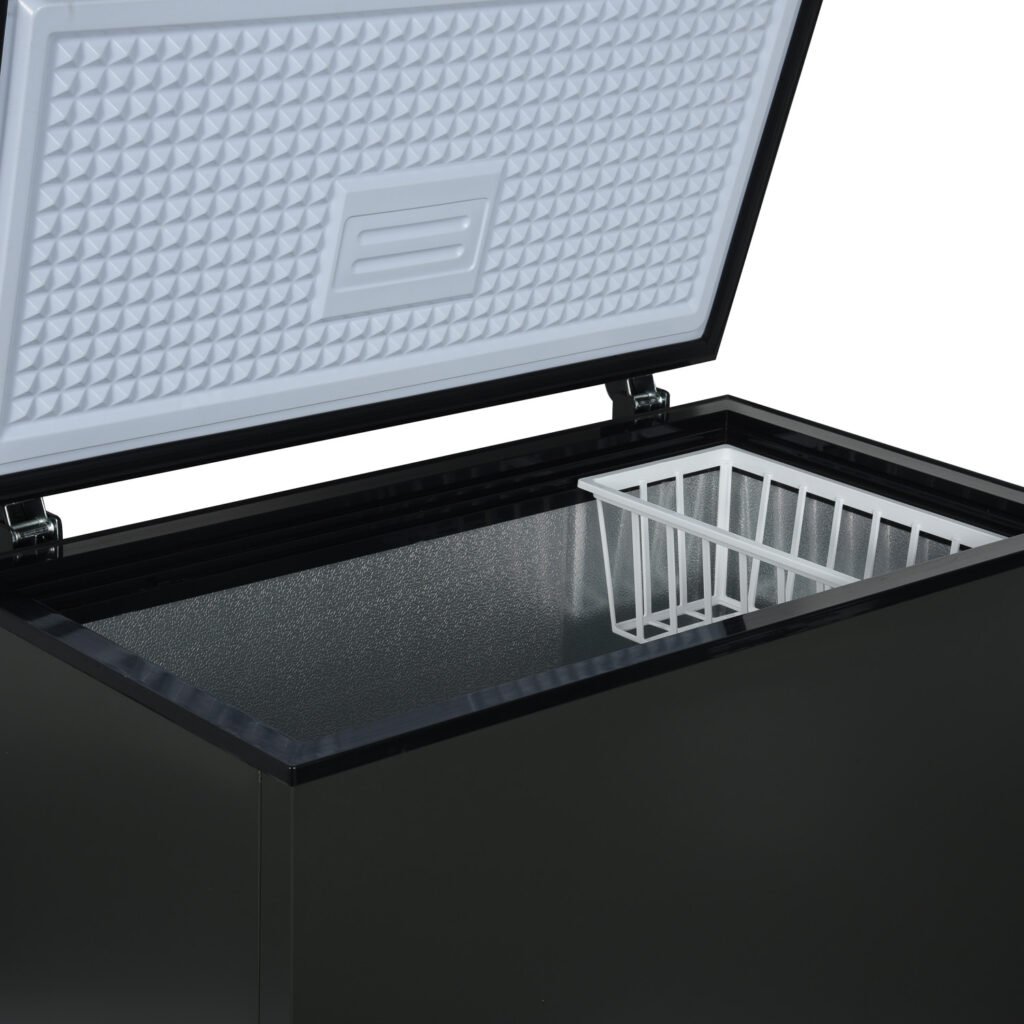

Upright freezers are defined by their tall, narrow cavities (typically 150-220cm tall) and need to maintain -18℃ to -22℃ – the critical temperature range for long-term food preservation. Achieving this requires insulation that’s uniform from top to bottom (no thin spots that cause frost buildup or energy waste) and dense enough to resist temperature leaks from frequent door openings.

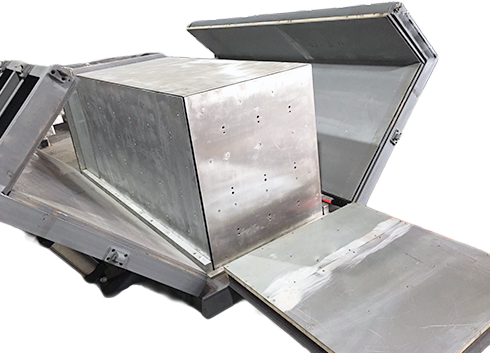

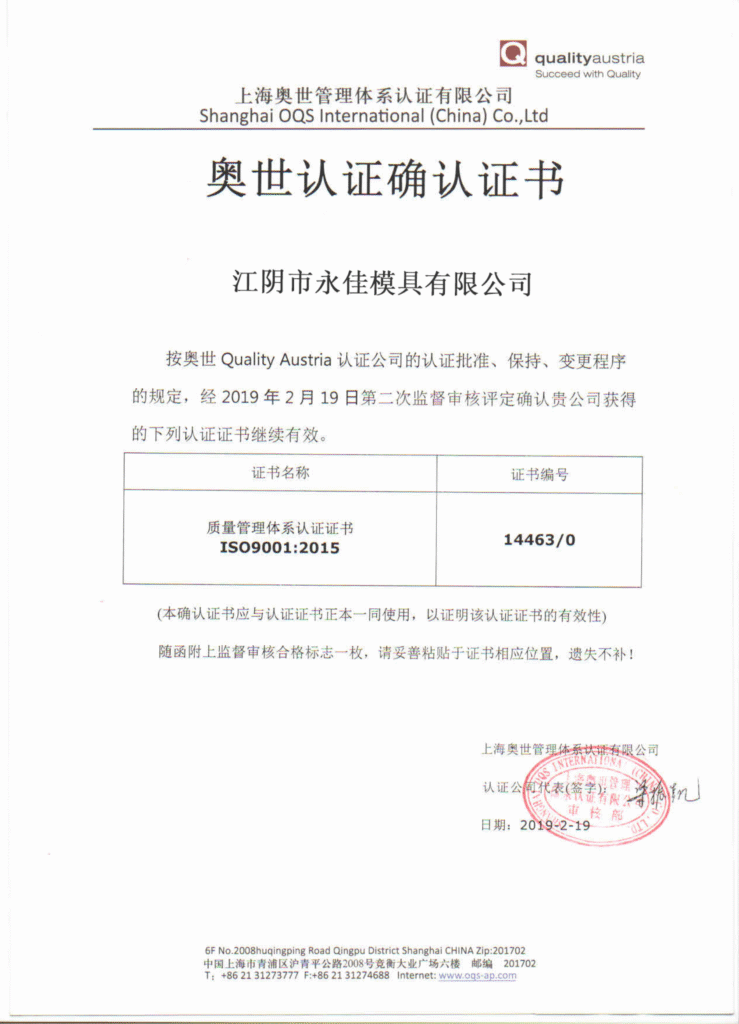

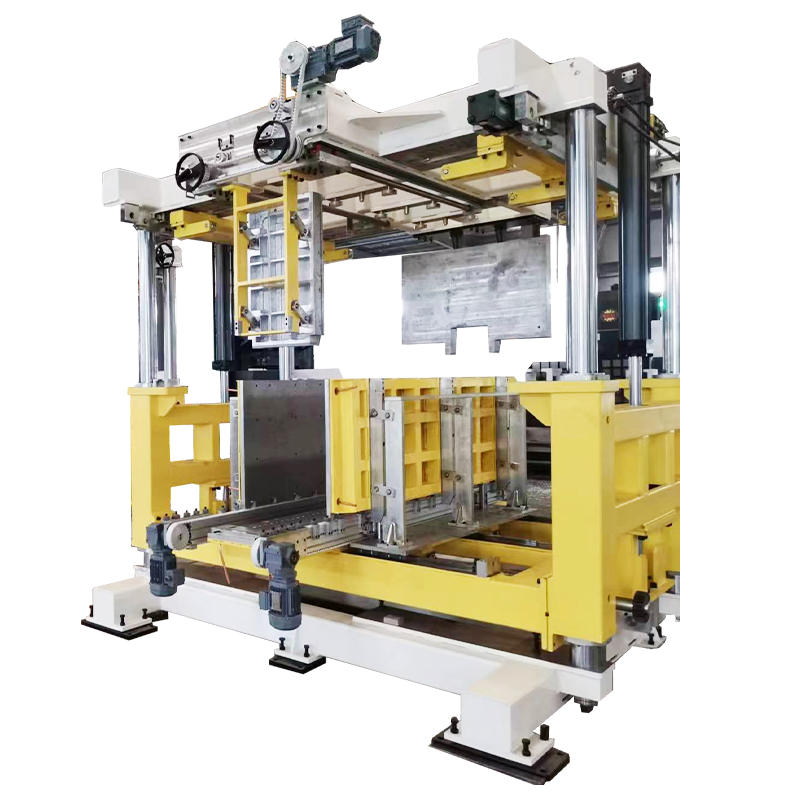

UREXCEED’s PU molds for upright freezers are engineered specifically for these challenges. Unlike generic molds (which struggle with tall cavities and uniform filling), our designs ensure consistent foam density across the entire height of the freezer, integrate seamlessly with door seals and cooling systems, and withstand the rigors of high-volume production. Whether you’re manufacturing 100L compact units or 500L family-sized freezers, our molds deliver the insulation precision that makes upright freezers efficient, reliable, and compliant with global energy standards.

Different Types Upright Freezer UREXCEED PU Mold Power

UREXCEED PU molds are suitable for the manufacture of a variety of upright freezers, whether they are Household Upright Freezers or Commercial Upright Freezers.

Household Upright Freezers

Family-Sized Upright Freezers

Compact Upright Freezers

Commercial Upright Freezers

What Makes UREXCEED Upright Freezer PU Molds Unique

Show more details of UREXCEED PU mold and let customers understand why choose our pu mold for upright freezer making.

Precision for tall cavity insulation

Upright freezers’ greatest challenge is uniform insulation in tall, narrow spaces – our molds solve this:

Strategic gating and venting systems ensure foam distributes evenly from the bottom to the top of 220cm-tall cavities, eliminating air pockets or thin spots that cause temperature inconsistencies.

CNC-machined to ±0.1mm accuracy, ensuring foam fits perfectly with inner liners, outer shells, and door gaskets – critical for preventing cold air leakage around edges.

Mold cavity designs enforce 35-50 kg/m³ foam density (ideal for deep freeze insulation) with ±2 kg/m³ uniformity – no “soft spots” that degrade over time in tall units.

High-grade alloy steel (S70C) frames with reinforced vertical supports to prevent warping in tall molds, even after 150,000+ production cycles.

Cavity walls treated to HRC 52-55 hardness, resisting wear from repeated foam injection and mold release – extending mold lifespan by 40% vs. standard alternatives.

Specialized coatings protect against polyurethane chemical residues and cleaning agents, reducing maintenance downtime by 25%.

Durability for high-volume production

Upright freezers are mass-market appliances – our molds keep up with production demands:

Precision Filling of Compact Cavities to Maximize Storage Space

Space in bar fridges is precious, and traditional molds often cause uneven foam distribution leading to: ① Uneven inner walls (wasting 5-8% storage space); ② Local over-thickness (increasing cabinet depth). Our molds address these with two key designs

Four micro-gates (3mm diameter) are placed in 60cm-wide cavities, with PLC-controlled injection volume (±1g error) ensuring uniform foam filling from all sides to center. Inner wall flatness reaches 0.5mm (vs. 1.5mm for traditional molds).

Mold cavity design supports ultra-thin 20-25mm insulation layers (traditional molds require 30mm), increasing internal storage space by 12% for the same external dimensions (e.g., a 60cm-wide fridge can hold 3 more standard wine bottles).

Rounded transitions (R=5mm) replace right-angle cavities, combined with side micro-vent holes (0.1mm) to eliminate 99% of corner air bubbles (traditional molds have >8% corner bubble rate).

Technical Specifications of PU Mold for Upright Freezer

| Parameter | Details |

|---|---|

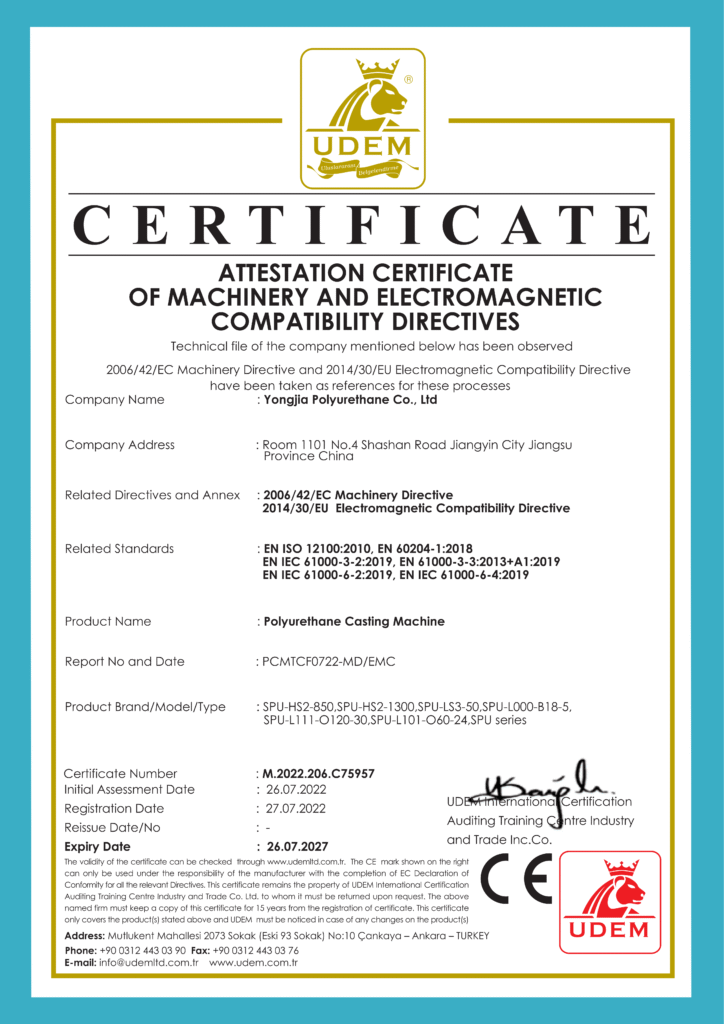

| Material | High-grade alloy steel (S70C) |

| Surface Treatment | Hardened (HRC 52-55) + anti-corrosion coating |

| Tolerance | ±0.1mm |

| Maximum Mold Height | 250cm (accommodating 600L+ upright freezers) |

| Production Cycles | 150,000+ cycles (before major overhaul) |

| Compatible Foam Density | 30-55 kg/m³ (optimized: 35-50 kg/m³) |

| Custom Design Lead Time | 3 weeks (standard sizes); 5 weeks (extra-tall/custom features) |

| Warranty | 5-year structural warranty; 1-year on wear parts |

Ready to Craft Upright Freezer That Protect & Impress?

Tell us the size, style, and daily output, and we will customize the equipment solution for you.

More About UREXCEED PU Mold for Upright Freezer

- Design Collaboration: Our engineers analyze your upright freezer specs (height, features, insulation needs) to optimize mold flow channels and cavity design.

- 3D Simulation: Foam flow simulation before production to identify and fix potential density issues in tall cavities.

- Lifetime Maintenance: Regular inspections, cleaning, and wear part replacement to ensure 150,000+ cycles of consistent performance.

- Training: On-site guidance for your team on mold handling, foam injection best practices, and troubleshooting tall cavity filling.

PU Mold for Upright Freezer

Customer Case Study

FAQs of PU Mold for Upright Freezer

More questions of UREXCEED PU mold you may want to know for manufacturing upright freezer.

Solution: Custom PU molds from UREXCEED, engineered for tall cavity uniformity and material efficiency.

A leading Asian manufacturer producing 50,000+ upright freezers annually for global markets.Client Quote

“UREXCEED’s molds solved our biggest upright freezer challenge: uniform insulation in tall units. Our customers notice the difference in frost-free performance, and our bottom line benefits from reduced waste.”